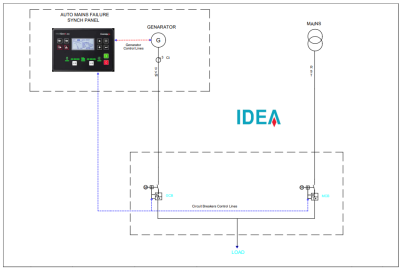

Single Grid Single Generator Synchronization

Suitable for facilities/operations with critical load applications (such as glass cutting, rolling mill, hospital). In planned outages, the approximate time of the outage is notified in advance by the main distribution company. The diesel generator is started before this time interval. It synchronizes by matching its voltage, frequency and phase angle with the grid and starts to provide partial power with as little load as possible (Forward Synchronization). In case of a blackout, the plant does not feel the power cut.

In addition, when the grid energy is restored, the generator smoothly transfers the load to the grid without interruption, remains in synchronization until the end of the period determined for the grid to be reliable, and at the end of this period, it switches off the circuit and goes to the stationary position after cooling operation. (Backward Synchronization) Except for the planned interruption, it is often unpredictable when the grid energy will be cut off. Like the generators programmed for automatic operation, the diesel set starts and starts the moment the grid energy is cut off and feeds the load. When the grid energy comes back, it performs the load transfer process without making the operation feel that the grid energy is coming back with the Reverse Directional Synchronization feature and switches to the stationary position after the cooling operation.

IDEA generator offers solutions for all synchronous systems from single grid – single generator, synchronization of multiple generators and multi-generator – multi-grid synchronous systems.

We provide project design, design, production and commissioning services in accordance with the desired operating scenario in MV/LV systems in accordance with the specification or single line scheme.

Single Grid Single Generator Synchronization is suitable for facilities/operations with critical load applications (such as glass cutting, rolling mill, hospital). In planned outages, the main distribution company informs the plant in advance about the approximate time of the outage.

Single Grid Single Generator Synchronization is suitable for facilities/operations with critical load applications (such as glass cutting, rolling mill, hospital). In planned outages, the approximate time of the outage is notified in advance by the main distribution company. The diesel generator is started before this time interval. It synchronizes by matching its voltage, frequency and phase angle with the grid and starts to feed the system by taking the load on itself (Forward Synchronization). When an outage occurs, the plant does not feel the power cut.

In addition, when the grid energy is restored, the generator smoothly transfers the load to the grid without interruption, stays in synchronization until the end of the period determined for the grid to be reliable, and after this period, it switches to the stationary position after cooling operation. (Backward Synchronization) Except for the planned outage, it is often unpredictable when the grid energy will be cut off. Just like the generators programmed for automatic operation, the diesel set starts at the moment the grid energy is cut off and feeds the load. When the grid energy is restored, it performs the load transfer process with the Backward Synchronization feature without making the operation feel that the grid energy is coming and goes out of the circuit and goes to the stationary position after the cooling operation.