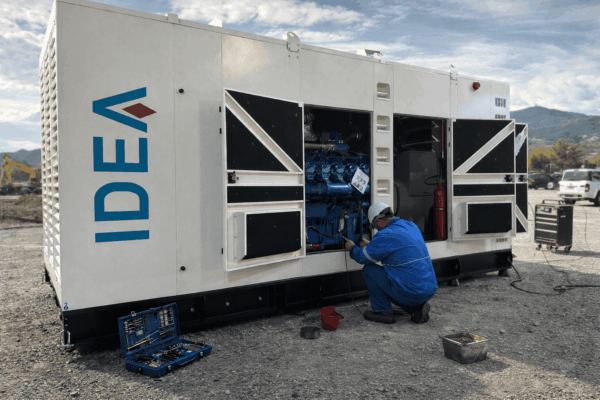

How to Establish a Diesel Generator Maintenance Routine?

Diesel generators are machines used to ensure uninterrupted supply of critical power needs. Reliable operation of these systems is possible not only through choosing the right model, but also through a planned and systematic maintenance routine.

Why Should a Standard Maintenance Routine Be Established?

Unplanned or irregular maintenance practices can lead to unexpected failures, high repair costs, power outages, and a shortened generator lifespan.

A standardized maintenance routine, on the other hand, provides operational continuity, cost control, and system safety for businesses.

How Is a Diesel Generator Maintenance Routine Planned?

When creating a maintenance routine, the following criteria should be taken into account:

- Generator operating hours

- Frequency of use (emergency / continuous)

- Environmental conditions (dust, humidity, temperature)

- Manufacturer’s maintenance recommendations

Maintenance activities are generally classified as daily, weekly, monthly, and periodic (250–500 hours).

Detailed Diesel Generator Maintenance Checklist

1. Daily / Pre-Operation Checks

- ☐ Fuel level check

- ☐ Engine oil level check

- ☐ Coolant level check

- ☐ Battery voltage and terminals

- ☐ Visual inspection for leaks and loose parts

- ☐ Indicator and alarm status

These checks are critical to confirm that the generator is ready for operation.

2. Weekly Maintenance Checks

- ☐ Test operation of the generator

- ☐ Check for abnormal noise and vibration

- ☐ Inspection of the exhaust system and connections

- ☐ General condition of the air filter

Weekly test runs ensure the generator is ready for emergency situations.

3. Monthly Maintenance Checks

- ☐ Battery charging system and alternator inspection

- ☐ Fuel filter condition

- ☐ Belt and fan tension

- ☐ Control panel connections

- ☐ Chassis and grounding inspection

At this stage, both mechanical and electrical systems should be evaluated together.

4. Periodic Maintenance (250–500 Hours)

- ☐ Engine oil change

- ☐ Oil filter replacement

- ☐ Fuel filter replacement

- ☐ Air filter replacement or cleaning

- ☐ General inspection of the cooling system

- ☐ Testing of sensors and protection systems

- ☐ Load test operation

This maintenance level is the most critical phase for long service life and high performance of the generator.

5. Annual / Comprehensive Maintenance

- ☐ Fuel tank cleaning

- ☐ Injector and fuel pump inspection

- ☐ Alternator insulation test

- ☐ AVR and voltage/frequency measurements

- ☐ Vibration and noise analysis

Annual maintenance is performed to analyze the overall condition of the system and to identify potential risks in advance.

Importance of Maintenance Records

After each maintenance activity, the date, operating hours, performed procedures, and replaced parts should be recorded. These records provide significant advantages for both technical monitoring and corporate audits.

An effective maintenance routine for diesel generators represents much more than just preventing failures. Properly planned and disciplined maintenance programs play a critical role in energy continuity, operational safety, and cost management.

For corporate facilities, generator maintenance should be regarded not merely as a technical requirement, but as a strategic investment.